DX51D Galvanized Pipe

Key Words:

Subclassification:

Galvanized Steel Pipe

WhatsAPP:

| Product name | galvanized steel pipe | |||

| Pipe end | plain end | |||

| Pipe Length | 3 meters-12 meters | |||

| Outside daimeter | 1/2 inch~8 inch | |||

| Pipe fittings | threaded, coupling, caps, flange, etc | |||

| Materials | Q195, Q235, Q235B, St37-2, St52, SS400, STK500, ASTM A53, S235JR | |||

| Standard | GB/T3091, ASTM A53, JIS G 3444, BS 1387 | |||

| Surface | galvanized | |||

| Zinc Coating | more than 60g/m2-600g/m2 | |||

| Payment term | T/T, L/C, Western Union, Cash, etc | |||

| Applications | water pipe, low fluid transportation, scaffolding pipe, greenhouse pipes | |||

| Certificate | ISO9001, SGS, TUV, BV | |||

Types of galvanizing process for plumbing pipes:

There are many different types of galvanizing processes depending on the desired outcome or properties of the finished product.

The most popular methods include hot-dip galvanizing, electroplating, mechanical electroplating, and plastic coating.

Hot-dip galvanizing is currently considered one of the best methods of galvanizing steel pipe due to its durability and corrosion resistance.

The method involves immersing the metal in a bath of molten zinc at 450 degrees Fahrenheit.

The process is complete when the steel pipe (or EN (European Standard) or ASTM (American Society for Testing and Materials))

standard material is coated with approximately 30 to 40 microns of pure zinc.

Electroplating is another popular method of galvanizing steel pipes because of its high-quality finish and relatively inexpensive cost

compared to other methods such as hot-dip galvanizing.

Electroplating uses an electric current to deposit a thin layer of chromium, nickel or zinc on an existing metal surface.

Mechanical plating, also known as mechanical polishing, is a low-cost alternative that involves adding a thin layer of zinc using a sandblasting (shot peening) method.

This type of galvanizing process is less popular due to its lower surface quality and its tendency to flake or peel.

Plastic coatingis the least used method of galvanized steel pipe due to its limited functionality and poor corrosion resistance.

Application of galvanized steel pipe:

After galvanizing, these metal pipes can be used in many different applications such as: water pipes, gas pipes, chemical pipes, sanitary pipes,

HVAC pipes and industrial pipes.

They are often used in building construction and water system development because they are very durable and last longer

other types of pipe such as PVC (polyvinyl chloride)

or copper pipe.Common applications for galvanized steel pipe are water and gas systems in building structures.

Because steel pipe is corrosion resistant, it's ideal for plumbing and HVAC (heating, ventilation, and air conditioning) applications that require durability.

They also make excellent chemical piping, as they withstand high levels of corrosion and rust better than other types of piping.

Benefits of using galvanized steel pipe:

There are many benefits to using galvanized steel pipe, such as excellent corrosion resistance, lower cost compared to other materials

such as PVC (polyvinyl chloride) or copper,

high durability and strength, and efficient heat transfer properties. Since they do not corrode or rust easily,

these metal pipes can be used in both indoor and outdoor applications. They're lightweight, easy to install,

and flexible enough to get around corners with ease,

yet strong enough to resist knocks from earthquakes or extreme weather conditions.

Factory

Shandong Jiugang Metal Products Co., Ltd. located in Shandong Province, with a factory area of 20000 square meters. We have obtained ISO9001 quality system certification and EU CE certification.

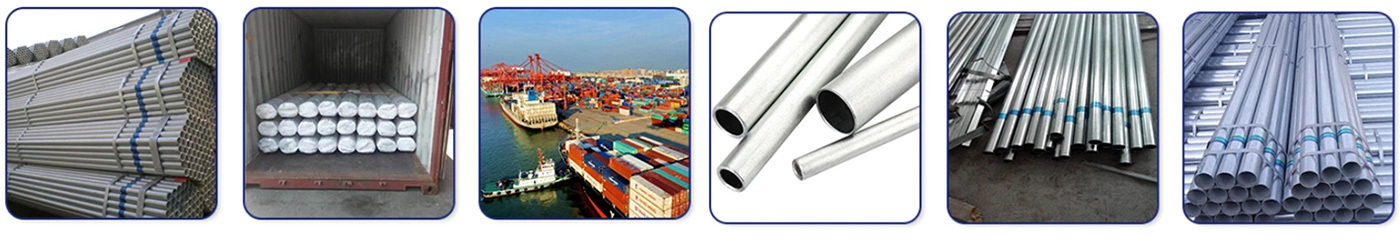

Packing And Delivery

We adhere to the management principle of "quality first, service first, continuous improvement and innovation, and customer satisfaction", with the quality goal of "zero defects, zero complaints". We are pleased to receive your inquiry and will reply as soon as possible.

Application

The main supply fields are: aerospace, national defense equipment, military weapons, chemical industry, shipbuilding, nuclear energy, trains, containers, environmental protection, precision machining, auto parts, machinery, electronic products, molds, medical treatment Equipment, construction, decoration, etc.

Related Products

FAQ

Q1: Are You Manufacture or Trade Company?

A1: We are the professional manufacturer of stainless/carbon/galvanized steel products located in China. Welcome to contact us and visit our factory before you place orders.

Q2: Can I get free samples?

A2: Of course you can. We can produce according to your samples or technical drawings. Contact us by whatsapp or email to get free samples and you will get the sample after 3-7 working days.

Q3: How do you guarantee the quality?

A3: We can send free samples to you, we can accept third-party testing. We also have test certificate, every batch goods will be testing before shipment, and the testing report will delivery to you with your goods.

Q4:How many coutries you already exported ?

A4: Exported to more than 50 countries mainly from Qatar, America, Russia, Belarus, Saudi Arabia, United Arab Emirates, Kuwait, Brazil, Egypt, Turkey, Jordan, India, etc.

Q5:How long is your delivery time?

A5:Within 5 days for stock size, 7-15 working days for customized size.

Q6: Can you OEM or ODM?

A6: Yes, we have a strong developing team. The products can be made according to your request

Q7: What is the MOQ?

A7: If you are scheduling to place a small quantity order or trial order, feel free to contact us, we can meet your requirements.

Q8:What are the certifications for your products?

A8:We have ISO 9001, MTC, third parties' inspections are all available such SGS, BV ect.

Contact Us For Quotation